| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,CIP |

| Payment Terms: | L/C, T/T |

| Place of Origin: | Zhejiang, China (Mainland) |

| Means of Transport: | Ocean |

| Production Capacity: | 20 sets per month |

| Packing: | container plywood case | Delivery Date: | 30-45 days |

|---|---|---|---|

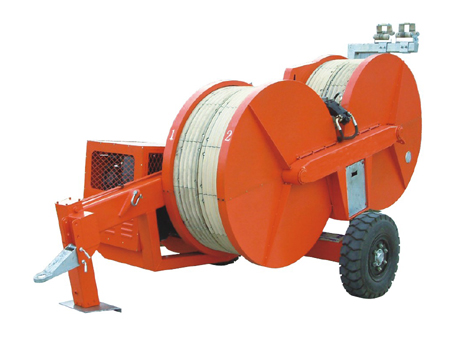

| Brand Name: | Dongfang | Overhead Line Stringing Equipment: | 8 Ton Overhead Lines Tensioner |

| Model: | SA-YZ2X40 | Max. Tension force: | 8 Ton 80 KN |

| Max. Stringing Speed: | 5 km per hour | Max. pulling back force: | 8 Ton 2X40 KN |

| Max. pull back speed: | 2X1.5 km per hour | Max. diameter of conductor: | 40 mm |

| Quantity of conductors: | 2 conductors |

8 Ton Hydraulic Tensioner is used for two or single conductors stringing on 275 or 330 KV transmisson line. It is equipped with Germany Deutz diesel engine, Germany Rexroth hydraulic pump, Italian R.R. reducer, AKG radiator, and Wika Hydraulic instrument.

Ningbo Dongfang Macinery of Power Co., Ltd. designs and manufactures complete range of hydraulic tensioners for overhead transmission line from 1990's. Ningbo Dongfang is the sole manufacture who can provide whole set of tension stringing equipment and tools for the overhead transmission line and underground cable stringing in China. We designed hydraulic conductor tensioner for overhead transmission line up to 24 tons capacity, the big hydraulic conductor tensioner 4 X 60 KN can be used for big conductors stringing up to 45mm diameter, with 4 independent hydraulic motors for driving four sets of bull wheels.

From 1980's, the Chinese engineering companies started using hydraulic conductor tensioner instead of mechanical friction tensioner on transmission line construction. (It is still used in some area and some countries). First, the hydraulic conductor tensions were used in 500KV transmission line, then 220 KV and 330 KV transmission line. Chinese manufacture started to make hydraulic conductor tensioner from the end of 1980, the production level is almost same as the world leading manufacture now.

Compare to the mechanical friction tensioner, the hydraulic conductor tensioner have following features:

1) The Tension force of hydraulic tensioner can be controlled stepless, the tension force is stable in the stringing.

2) The hydraulic system of Tensioner has over load protection system, the max. tension force of conductor tensioner could be pres-set, this function could protect the conductor and reduce the wear of machine parts. The operation prevent the wear of conductors in the stringing, and reduce the electric power loss caused by corona.

3) The cooling system of hydraulic tensioner is also driven by hydraulic oil, it is more efficient and stable.

4) The modern hydraulic conductor tensioners are equipped with high performance discharge pump and hydraulic motors, for setting up closed hydraulic circuit system. The hydraulic reaction speed is very fast and sensitive. Most of hydraulic tensioners also have pulling functions.

5) The hydraulic system also can be electric controlled include the hydraulic pump and hydraulic valve, the tension procedure could be registered by computer, and remote controlled.

Most of Chinese engineering companies are using hydraulic conductor tensioners in their overhead transmission line construction now.

Hydraulic Tensioner SA-YZ2X40B for 2 bundled conductors

Item No. | 07192 |

Model | SA-YZ 2X40B |

Max. Tension Force (KN) | 2X40 or 1X80 |

Continuous Tension Force (KN) | 2X35 or 1X70 |

Max. Stringing Speed(km/h) | 5 |

Max. Pullback force (KN) | 2X40 or 1X80 |

Max. Pullback speed (km/h) | 2 X 1.2 |

Diameter of wheel (mm) | Φ1500 |

Number of grooves | 2X5 |

Max. Conductor Diameter (mm) | Φ40 |

Model of Engine | DEUTZ AIR COOLED |

Power of Engine | 51 KW |

Rotate Speed of Engine (rpm) | 2500 |

Electrical system: | DC24V |

Weight (kg) | 4850 |

Dimension (m) | 4.50 x 2.20 x 2.80 |

Application: It is suitable to string two bundled conductors or single conductor in overhead transmission line.

Features:

- Closed hydraulic circuit, infinitely variable tension force control in both directions.

- The max. tension/pull back force for conductor stringing operation can be presetted, the tension /pull back force can be read from the tension gauge of machine.

- Spring applied hydraulic released brake acts automatically in case of hydraulic failure to ensure line safety

- Hydraulic oil cooling system

- Bull wheels lined with wear proof MC nylon lining segments

- With 2 hydraulic power outlets to control 2 sets of hydraulic reel stands.

- Hydraulic front jack

- Mounted on trailer with rigid axle for towing at max. speed of 15 km/h

Main components:

- Engine: Deutz air-cooled diesel engine (Made in China)

- Main variable displacement pump and main motor: Rexroth (German)

- Reducer: R.R. (Italian)

- Main hydraulic valves: Rexroth (German)

- Hydraulic Instrument: WIKA

- Quick couplings: EMB

- Radiator: AKG

- Optional Deutz air-cooled diesel engine (Made in German) SA-YZ2X40A 07191.

We have designed and manufactured whole series of tensioners for single conductor to six bundled conductors stringing from 33 KV up to 1000 KV transmission line construction.

Our Series of Hydraulic Conductor Tensioner

Model | Max. Tension Force | Usage | Max. Diameter of Conductor |

SA-YZ30A | 30 KN | Single conductor or OPGW | 32 mm |

SA-YZ40A | 40 KN | Single conductor or OPGW | 40 mm |

SA-YZ2X35 | 70 KN | Single or Two Conductors | 32 mm |

SA-YZ2x40 | 80 KN | Single or Two Conductors | 40 mm |

SA-YZ2X50 | 100 KN | Single or Two Conductors | 40 mm |

SA-YZ2X55 | 110 KN | Single or Two Conductors | 40 mm |

SA-YZ2X70 | 140 KN | Single or Two Conductors | 42 mm |

SA-YZ2X80 | 160 KN | Single or Two Conductors | 45 mm |

SA-YZ2X80S | 160 KN | Four or Two conductors | 40 mm |

SA-YZ4X40 | 160 KN | Four or Two conductors | 40 mm |

SA-YZ2X90 | 180 KN | Single or Two Conductors | 45 mm |

SA-YZ4X45 | 180 KN | Four or Two conductors | 40 mm |

SA-YZ4X50 | 200 KN | Four or Two conductors | 45 MM |

Shipment

1. The machine will be shipped in container

2. We will ship the products within one month normally after receiving the payment.

3. Stock is available for standard product.

Package

1. The machine will be loaded in container and fixed with steel wire rope.

2. The accessory and operation manual will be packed in plywood case.

Payment

1. We accept T/T and L/C.

2. Please send swift copy of T/T if you arrange payment by T/T

3. Please send us the L/C draft to us before issue L/C.

Why choose us:

1. High quality and competitive price, more than 30 engineers working in the design and quality control department.

2. Leading and biggest manufacture for stringing equipment in China.

3. 25 years of production experience and more than 1000 customers in the country and abroad market. The set of 4 ton puller and 3 ton tensioner have been sold to more than 20 countries.

4. Big stock condition for fast shipment.

5. Detailed pre-sales service and fast active after-sales service. Response within 12 hours after-sales service

Category: Conductor Tensioner Stringing Equipment