| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,DDP |

| Payment Terms: | L/C, T/T |

| Place of Origin: | Zhejiang, China (Mainland) |

| Means of Transport: | Ocean, Land |

| Production Capacity: | 10 sets per month |

| Packing: | container tools in... | Delivery Date: | 30-45 days |

|---|---|---|---|

| Brand Name: | Dongfang | Description of Product: | Overhead Transmission Line Stringing Equipment |

| Voltage: | 220 KV 230KV | Diameter of single conductor: | Max. 40 mm |

| Max. Pulling Force: | 90 KN 9 Ton | Max. Tension Force: | 80 KN 8 Ton |

| Max. Stringing Speed: | 5 km per hour | Quantity of Conductor: | Two conductors |

Transmission Line Stringing Equipments are used for conductors or OPGW stringing, We used 9 Ton puller with 8 Ton tensioner for two conductors stringing on 220KV transmission line.

Hydraulic Conductor Stringing Equipment

Item No. | Model | Description | Pulling Force | Tension Force | Remark |

07001 | SA-YQ30 | 3 ton hydraulic puller | 30 KN |

|

|

07011 | SA-YQ40 | 4 ton hydraulic puller | 40 KN |

| CUMMINS |

07031 | SA-YQ60 | 6 ton hydraulic puller | 60 KN |

| CUMMINS |

07041 | SA-YQ90 | 9 ton hydraulic puller | 90 KN |

| CUMMINS CHINA |

07042 | SA-YQ90D | 9 ton hydraulic puller | 90 KN |

| CUMMINS AMERICA |

07051 | SA-YQ180G | 18 ton hydraulic puller | 180 KN |

| CUMMINS CHINA |

07052 | SA-YQ180 | 18 ton hydraulic puller | 180 KN |

| CUMMINS AMERICA |

07061 | SA-YQ220 | 22 ton hydraulic puller | 220 KN |

| CUMMINS |

07065 | SA-YQ250 | 25 ton hydraulic puller | 250 KN |

| CUMMINS |

07071 | SA-YQ300 | 30 ton hydraulic puller | 300 KN |

| CUMMINS |

07075 | SA-YQ400 | 40 ton hydraulic puller | 420 KN |

| CUMMINS |

07155 | SA-YZ30A | 3 ton hydraulic tensioner | 20 KN | 30 KN | Single conductor |

07156 | SA-YZ30B | 3 ton hydraulic tensioner | 20 KN | 30 KN | Single conductor |

07171 | SA-YZ40A | 4 ton hydraulic tensioner | 40 KN | 40 KN | Single conductor |

07181 | SA-YZ2X35 | 7 ton hydraulic tensioner | 60 KN | 70 KN | Two conductors |

07191 | SA-YZ2X40A | 8 ton hydraulic tensioner | 80 KN | 80 KN | Two conductors |

07192 | SA-YZ2X40B | 8 ton hydraulic tensioner | 80 KN | 80 KN | Two conductors |

07195 | SA-YZ2X55 | 10 ton hydraulic tensioner | 100 KN | 110 KN | Two conductors |

07196 | SA-YZ2X70 | 14 ton hydraulic tensioner | 120 KN | 140 KN | Two conductors |

07198 | SA-YZ2X90 | 18 ton hydraulic tensioner | 180 KN | 180 KN | Two conductors |

07201 | SA-YZ4X50 | 20 ton hydraulic tensioner | 180 KN | 200 KN | Four conductors |

07202 | SA-YZ4X40 | 16 ton hydraulic tensioner | 160 KN | 160 KN | Four conductors |

07203 | SA-YZ2X80F | 16 ton hydraulic tensioner | 160 KN | 160 KN | Four conductors |

07212 | SA-YZM7.5 | 0.75 ton hydraulic tensioner |

| 7.5 KN | OPGW or ADSS |

07223 | SA-YQZ40C | 4 ton hydraulic puller/tensioner | 40 KN | 40 KN | re-conductoring |

07224 | SA-YQZ40D | 4 ton hydraulic puller/tensioner | 40 KN | 40 KN | re-conductoring |

07228 | SA-YQZ60 | 6 ton hydraulic puller/tensioner | 60 KN | 60 KN | re-conductoring |

1. SA-YQ90D Hydraulic Puller

Item No. | 07042 |

Model | SA-YQ90D |

Stringing capacity | 1 pilot steel wire rope |

Max. Pulling Force (KN) | 90 |

Max. Continuous Pulling Force (KN) | 80 |

Speed at Max. continuous pull: | 2.5km/h |

Max. Pulling Speed (m/min) | 5km/h |

Root Diameter of Bull wheel (mm) | Φ520 |

Number of grooves | 7 |

Max. Steel rope Diameter (mm) | Φ21 |

Model of Diesel Engine | Water cooled diesel engine |

Power of Diesel Engine | 121 KW |

Rotate Speed of Engine (rpm) | 2500 |

Electrical System | DC24V |

Weight (kg) | 4300 |

Dimension (m) | 4.3 x 2.1 x 2.5 |

Application: The hydraulic puller is used to pull four bundled conductors or 2 bundled conductors for power line construction. It is fully hydraulic controlled, easily used and maintained

Features:

- Closed hydraulic circuit,infinitely variable speed control in both rotating directions.

- The max pulling force for stringing operation can be preset, pulling force in the rope can be read on the line pull gauge.

- Automatic over pulling protection system

- Spring applied hydraulic released brake acts automatically in case of hydraulic failure to ensure safety.

- Hydraulic oil cooling system.

- Heat treated wear-proof bull wheels

- With rigid axle for towing at high speed, the machine looks beautiful.

- Hydraulic actuated pulling rope clamp for convenient reel change.

- Integral self-loading reel winder with automatic level wind.

Main Components:

- Engine: Cummins water-cooled diesel engine.

- Main variable displacement hydraulic pump and main motor: Rexroth (German)

- Reducer: Rexroth. (Germany)

- Reel winder motor: Danfoss (Danish)

- Main hydraulic valves: Rexroth (Germany

- Hydraulic instruments: WIKA (German)

- Radiator: AKG (German)

- The hydraulic reel winder is equipped with 1400mm diameter steel drum (GSP1400)

2. 7 Ton Hydraulic Tensioner SA-YZ2X35 for 2 bundled conductors

Item No. | 07181 |

Model | SA-YZ 2X35 |

Max. Tension Force (KN) | 2X35 or 1X70 |

Continuous Tension Force (KN) | 2X30 or 1X60 |

Max. Stringing Speed(km/h) | 5 |

Max. Pullback force (KN) | 2X30 or 1X60 |

Max. Pullback speed (km/h) | 2 X 1.2 |

Diameter of wheel (mm) | Φ1200 |

Number of grooves | 2X5 |

Max. Conductor Diameter (mm) | Φ32 |

Model of Engine | CUMMINS WATER COOLED |

Power of Engine | 38 KW |

Rotate Speed of Engine (rpm) | 2500 |

Electrical system: | DC24V |

Weight (kg) | 4000 |

Dimension (m) | 4.10 x 2.10 x 2.60 |

Application: It is suitable to string two bundled conductors or single conductor in overhead transmission line.

Features:

- Closed hydraulic circuit, infinitely variable tension force control in both directions.

- The max. tension/pull back force for conductor stringing operation can be presetted, the tension /pull back force can be read from the tension gauge of machine.

- Spring applied hydraulic released brake acts automatically in case of hydraulic failure to ensure line safety

- Hydraulic oil cooling system

- Bull wheels lined with wear proof MC nylon lining segments

- With 2 hydraulic power outlets to control 2 sets of hydraulic reel stands.

- Hydraulic front jack

- Mounted on trailer with rigid axle for towing at max. speed of 15 km/h

Main components:

- Engine: Cummins water-cooled diesel engine

- Main variable displacement pump and main motor: Rexroth (German)

- Reducer: R.R. (Italian)

- Main hydraulic valves: Rexroth (German)

- Hydraulic Instrument: WIKA

- Quick couplings: EMB

- Radiator: AKG

3. Hydraulic Tensioner SA-YZ2X40B for 2 bundled conductors

Item No. | 07192 |

Model | SA-YZ 2X40B |

Max. Tension Force (KN) | 2X40 or 1X80 |

Continuous Tension Force (KN) | 2X35 or 1X70 |

Max. Stringing Speed(km/h) | 5 |

Max. Pullback force (KN) | 2X40 or 1X80 |

Max. Pullback speed (km/h) | 2 X 1.2 |

Diameter of wheel (mm) | Φ1500 |

Number of grooves | 2X5 |

Max. Conductor Diameter (mm) | Φ40 |

Model of Engine | DEUTZ AIR COOLED |

Power of Engine | 51 KW |

Rotate Speed of Engine (rpm) | 2500 |

Electrical system: | DC24V |

Weight (kg) | 4850 |

Dimension (m) | 4.50 x 2.20 x 2.80 |

Application: It is suitable to string two bundled conductors or single conductor in overhead transmission line.

Features:

- Closed hydraulic circuit, infinitely variable tension force control in both directions.

- The max. tension/pull back force for conductor stringing operation can be presetted, the tension /pull back force can be read from the tension gauge of machine.

- Spring applied hydraulic released brake acts automatically in case of hydraulic failure to ensure line safety

- Hydraulic oil cooling system

- Bull wheels lined with wear proof MC nylon lining segments

- With 2 hydraulic power outlets to control 2 sets of hydraulic reel stands.

- Hydraulic front jack

- Mounted on trailer with rigid axle for towing at max. speed of 15 km/h

Main components:

- Engine: Deutz air-cooled diesel engine (Made in China)

- Main variable displacement pump and main motor: Rexroth (German)

- Reducer: R.R. (Italian)

- Main hydraulic valves: Rexroth (German)

- Hydraulic Instrument: WIKA

- Quick couplings: EMB

- Radiator: AKG

- Optional Deutz air-cooled diesel engine (Made in German) SA-YZ2X40A 07191.

3. MECHANICAL DRUM ELEVATOR 70 KN

Item No. | Model | Accommodated Reel | Brake force (N.m) | Line speed (m/min) | Weight (kg) | |||

Diameter (mm) | Width (mm) | Bore (mm) | Max. Weight | |||||

15143 | SIPZ-7 | Φ1800-2500 | ≤1700 | Φ120 | 70 KN | 2000 | 80 | 480 |

Application: It is used to raise and support reels in conductor stringing operations. The reel could be controlled by both sides of disc brake.

Features: It could be dismantled into 5 pieces, easy for transportation.

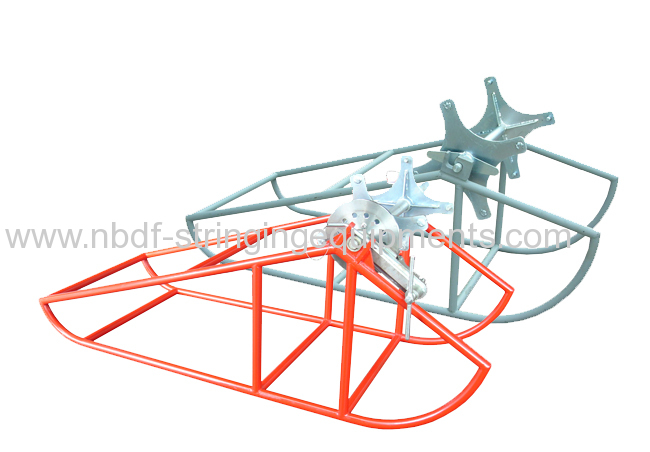

4. CRADLE REEL ELEVATOR .

Item No. | Model | Reel Size (mm) Diameter X Width | Working load (KN) | Weight (kg) |

07128-3 | SE-1400J | Φ1400 X 560 | 20 | 85 |

Application: It is used for paying out or taking back pilot steel wire rope on site.

The reel elevator is made of welded steel with protective coating. The parts are completely

Detachable for easy transportation. Brake system is optional.

5. 3 SHEAVES CONDUCTOR PULLEYS

Item No. | Model | Rated Load (KN) | Conductor Range (mm) | Material of sheave | Weight (kg) |

10142 | SHSQN822 | 60 | ≤36 mm | Nylon | 118 |

Application: The three sheaves stringing blocks could be used for two or three bundled conductors stringing. All the sheaves are made of MC nylon. The central sheave is specially strengthened. it is good for passing both steel rope and conductors. All the sheaves are mounted on ball bearings. The frame of blocks is made of galvanized steel.

6. Balance Running Board for Two bundled conductors

Item No. | Model | Rated Load (KN) | Pulley Size (mm) | Conductor Condition | Weight (kg) |

17223 | SZ2A-8 | 80 | Φ822 X 110 | 2 bundled conductors | 106 |

Application: The Head board is used for pulling 2 bundled conductors.

The whole set is included one of 8 ton head swivels (connected with pilot steel wire rope ) and two of 5 ton swivel joints(connected with conductor grips).

The steel wire rope is going through the centre pulley to connect two conductors.

7. Single nylon sheave stringing blocks for Earth Wire

Item No. | Model | Stranded steel rope Range (mm²) | Rated Load (KN) | O. D. of Sheave (mm) | Sheave Width (mm) | Weight (kg) | Material |

10344 | SHTN-200 X 60 | ≤150 | 20 | Φ200 | 60 | 3.8 | Nylon |

Application: It is used for stringing overhead earth wires. The sheave is made of high strength nylon, which is good for passage of earth wire. The roller is mounted on the ball bearings, and the frame of roller is made of galvanized steel.

8. HEAD BOARD FOR OPGW

Item No. | Model | Rated load (KN) | Anti-twisting torque force (N.m) | OPGW size range (mm) | Overall weight (kg) |

20118 | ZB1 | 20 | 32 | 11-16 | 2 X 12.5 |

Application: It is used for fiber optic cable stringing. The cable could be prevented spiraling by this tool. It is installed directly on the head of OPGW cable, with interval distance 2 meters for 2 pieces of devices.

9. Anti twisting braided steel wire rope

Item No. | Nominal diameter | Min. Breaking Load (KN) | Single strand diameter (mm) | Normal T/S (N/mm²) | Net Weight (kg/1000m) | |

18208A | 16 | 160.00 | Φ3.5 | 1960 | 800 | |

Anti twisting steel rope is specially braided from high strength, high flexible galvanized steel wire. The braided steel strand has high flexibility, complete stability to rotation under tension force. The wire rope is lubricated for long time usage.

It can homogeneously distribute the pressure between the elementary wires. The special rope can increase efficiency during the overhead transmission line stringing work. The rope is packed in steel drum which can be installed directly on the reel winder of puller.

STEEL DRUM

THE STEE REEL IS MADE OF TUBULAR STEEL AND PROTECTED AGAINST CORROSION. THE STEEL REEL IS DESIGNED FOR MOUNTING ON REEL WINDER OF HYDRAULIC PULLERS.

DIMENSIONS (MM) | Weight | |||

Item No. Model | A B | C | D | KG |

07125B GSP1250 | 420 560 | 570 | 1250 | 65 |

10. Double Layer braided PE Rope

Item No. | Model | Elongation with 30% Breaking load | Breaking Load | Weight | Material |

18171J | 16 mm | 1.5% | 80 KN | 180 kg/km | Polyester |

The PE rope is specially braided from double layer high strength polyester fiber, anti twisting and light weight. It is used as pilot rope or pulling rope in overhead transmission line stringing operation, it also can be used for hot line working.

The rope is double layer braided with spliced eye on both ends. The outer layer is braided from 16 strands fiber wire, inner layer is braided from 8 strands fiber core.

11-12. Ratchet Lever Hoist with chain.

MODEL | HSH-CII1.5 | HSH-CII3 | HSH-CII6 | |

Item No. | 14222 | 14232 | 14242 | |

CAPACITY (TONS) | 1.5 | 3 | 6 | |

STANDARD LIFT (M) | 3 | 3 | 3 | |

RUNNING TEST LOAD (KN) | 22.5 | 37.5 | 75.0 | |

EFFORT REQUIRED TO LIFT RATED LOAD (N) | 220 | 320 | 340 | |

STRAND NO. OF LOAD CHAIN | 1 | 1 | 2 | |

LOAD CHAIN DIAMETER (MM) | 8 | 10 | 10 | |

DIMENSIONS (MM) | A | 203 | 215 | 200 |

B | 118 | 130 | 130 | |

C | 155 | 200 | 200 | |

D | 45 | 50 | 64 | |

H | 380 | 480 | 600 | |

L | 370 | 410 | 410 | |

K | 36 | 40 | 50 | |

NET WEIGHT (KG) | 11.8 | 21 | 32 | |

PACK MEASUREMENT (MM) | 46.5X15.5X19 | 51X19X21.5 | 53X22X21.5 | |

EXTRA WEIGHT OF PER METER | 1.4 | 2.2 | 4.4 | |

Application: It is used to lift goods or pulling the conductors during the sagging operation. The solid bearing is adopted in the joint of load sprocket wheel and wall panel, to improve the flexibility and working efficiency. Mechanical braking system is available for safety.

13. HYDRAULIC PRESS 125 TON

Item No. | Model | Max. Compress Force (KN) | Max. Oil Pressure (MPa) | Conductor Range (mm²) | Stroke (mm) | Weight (kg) |

16104 | QY-125 | 1250 | 94 | ≤ACSR720 | 25 | 40 |

Application: The hydraulic compressor head is used with motorised hydraulic pump for compression of conductor joint or earth wire joint. It is casted from high strength steel.

High Pressure Hydraulic Pump Station (Model: YBG-94WQ)

Item No. | Description | Hydraulic Pressure (MPa) | Oil Flow (L/min) | Power (KW) | Weight (kg) |

16146 | Gasoline motor driven hydraulic pump station mounted on hand cart | 75 | 1.5 | 4.41 | 68 |

Note: The pump stations only act as power sources for hydraulic compressors or other equipment.

The Gasoline motor is HONDA GX160.

The length of standard hydraulic Hose is 3 meters. Longer Hose is optional.

14. Hexagon Compression Die sets for Conductor & Earth Wire

Item No. | Matching Compressor | Specification of Hexagonal Die Set (Outer Diameter of Compression terminal, L for Aluminum compression terminal, G for steel terminal) |

16124 | QY-125 | L - 26, 28, 30, 32, 34, 36, 38, 40, 45, 50, 52, 55,60 mm G -12, 14, 16, 18, 20, 22, 24, 26 mm |

Note: the Hexagonal Die sets Size could be made according to the requirement of customer.

15. Hydraulic Cutter Suitable for ACSR Conductor

Item No. | Model | Cutting capacity | Weight (kg) | Style |

16243 | CPC-40A | ≤ACSR40 mm | 8 | One piece Handle |

The hydraulic cutter is suitable for cutting ACSR conductors up to diameter 40mm. The blade of cutter is made of alloy steel, which can be changed and provided separately.

16-17. Stringing Swivel Joints

Item No. | Model | Dimension of Connector (mm) | Working Load (KN) | Weight (kg) | ||||

A | B | C | D | E | ||||

17124 | SLX-3 | 37 | 129 | 95 | 16 | 16 | 30 | 0.65 |

17125 | SLX-5 | 42 | 154 | 116 | 18 | 17 | 50 | 1.5 |

17126 | SLX-8 | 57 | 220 | 165 | 24 | 22 | 80 | 2.4 |

Application: It is used to pull conductors. Constructed with ball bearings inside, to eliminate the torque force which stringing conductors. The product can not be used for connection of pilot ropes, because it can not pass through the bull wheels of puller.

18. U SHAPE BEND RESISTANCE CONNECTOR

Item No. | Model | Dimension of Connector (mm) | Rated Load (KN) | Weight (kg) | ||||

A | B | C | D | E | ||||

17114 | SLU-8 | 56 | 110 | 28 | 22 | 50 | 80 | 0.8 |

Application: The pilot wire connectors are specially designed and made to connect the pilot wire rope, and pulling rope to pass over the conductor pulleys, bull wheels of hydraulic puller or puller-tensioner. It is processed from high strength forged steel, and galvanised. The special profile minimizes the overload on the rope spliced eyes during the passage.

19. Aluminum alloy Conductor Come along Clamp

Item No. | Model | Working Load (KN) | Conductor Range | Weight (kg) | Material |

13225 | SKL-50 | 50 | Φ29-35 mm | 6.60 | Aluminum alloy |

13224A | SKL-40A | 40 | Φ28-30 mm | 5.0 | Aluminum alloy |

Application: It is specially used for adjustment of sagging of conductors, to hold the conductors temporarily during the stringing operation. The whole body and jaw is made of High strength Aluminum Alloy, light weight and good for protecting the surface of conductors.

20. SKDZ Model Earth Wire Grips (Automatic come along clamps for earth wires)

Item No. | Model | Rated Load (KN) | Wire Size Range (mm²) | Max. Opening (mm) | Weight (kg) |

13103 | SKDZ-2 | 20 | 50-70 | 14 | 2.9 |

Application:It is used for sagging of earth wires and adjustment of guy wires.

Material: It is forged from quality steel, with special jaw for holding tightly of earth wire.

21. Automatic Come Along Clamp for OPGW

Item No. | Model | Rated Load (KN) | Breaking Load (KN) | Wire Size Range DIA. (mm) | Max. Opening (mm) | Weight (kg) |

20103 | SKG-1.6 | 16 | 32 | 11-15 | 16 | 6 |

Application: It is used for sagging of OPGW and hold the OPGW temporarily

Material: It is forged from aluminium alloy. The jaw of clamp is specially designed for protection of OPGW cable.

22. 5 Ton Petrol Engine Powered Winches for lifing and sagging

Item No. | 09123 | |

Model | JJQ-50-B | |

Petrol Engine Power (hp) | 9 | |

Petrol Engine Model | Honda GX270 | |

Petrol Engine Speed (rpm) | 3600 | |

Pull force (KN) / Pull speed (m/min) | I shift | 12.5/18.5 |

II shift | 30/7.3 | |

III shift | 50/4.6 | |

Reverse shift | -/5.2 | |

Diameter of Capstan (mm) | Φ160 | |

Dimension (mm) | 870X620x520 | |

Weight (kg) | 135 | |

Application: it is used for pulling, lifting, tower erection and sagging operation in line construction.

Features: With mechanical automatic brake system. Light weight, easy to operate and maintain.

Note: Petrol Engine is Honda engine from Japan.

Why choose us:

1. High quality and competitive price, more than 30 engineers working in the design and quality control department.

2. Leading and biggest manufacture for stringing equipment in China.

3. 25 years of production experience and more than 1000 customers in the country and abroad market. The set of 9 ton puller and 8 ton tensioner have been sold to more than 20 countries.

4. Big stock condition for fast shipment.

5. Detailed pre-sales service and fast active after-sales service. Response within 12 hours after-sales service

Category: Transmission Line Stringing Equipment